Marine Set-Up

We sell all the components needed for a proper Marine Propane Boating Set-Up: Solenoids, Twin-Stage Regulators, Hoses, Brass Fittings, Leak Detectors, Pressure Gauges, Portable BBQs, and Cylinders (composite & aluminum).

We also provide professional advice and assistance with your Marine Propane Boating Set-Up.

Components of Standard Marine Set-Up

Typical boat setup (approx cost $150)

- Rubber pigtails come in different lengths – one in pic is 12” – also come 18”/24”/36”

- 12 volt solenoid ¼” inlet and ¼” outlet

- 0-200 psi gauge to check for leaks

- Twin stage regulator

Pressure Gauge

A pressure gauge is an essential safety feature, and it must be the first thing connected to the valve on top of the bottle. It can be mounted directly on the bottle or installed on the locker wall and connected to the bottle with a high-pressure pigtail.

The gauge does not tell you the level of the gas in the tank; you weigh the tank to determine that. What the pressure gauge does do is allow you to - easily and frequently – leak test the LPG system.

Electric Solenoids

Electric solenoids shut off the gas inside the locker with the flip of a switch that’s conveniently located in the cabin. Safe propane use means shutting off the gas at the tank after every use. You can do that manually by turning the knob on the tank; leaving the gas lines pressurized is not recommended. The solenoid makes it easy to cut the propane supply to the line. The switch should be paired with a bright panel light that warns you that the solenoid valve is open. The solenoid should always be off except when the system is in use.

Twin-Stage Regulator

From the solenoid, the gas should flow directly into a step-down regulator that reduces the pressure from 250 psi on the tank side (this varies widely with temperature) to 11″WC in the line that carries the gas to the galley stove or other appliance. This order can be reversed, with the solenoid plumbed after the regulator, but low-pressure solenoids tend to be of lesser quality. A high-pressure solenoid is preferable because it shuts off the gas upstream of the regulator and the rest of the system. In application, either configuration shuts off the gas inside the locker. If you install your solenoid on the high-pressure side, be sure it is rated for high pressure.

Supply Hoses

The fuel line from the regulator (or solenoid valve) to the stove must be continuous–no connections inside the boat except at the stove. Solid copper fuel lines are commonly used, but flexible, high-pressure hose is probably safer for boat use, and it is easier to install.

A threaded adapter can be required to connect the hose to the regulator or solenoid. Use thread sealant on the regulator end of the adapter but not on the end that the hose attaches to. Pipe fittings require gas tape or sealant, but flare and compression fittings do not.

The hose should exit the propane locker near the top, and it should pass through a vapor-tight fitting to prevent gas from leaking out of the locker into the interior of the boat. Use a similar fitting to protect the hose from abrasion everywhere it passes through a bulkhead.

Common straight-through fittings are too short to pass through a plywood bulkhead. You can thin the bulkhead by counter boring one side with a spade bit. Alternatively, cut an oversize hole through the bulkhead with a hole saw, screw a metal or fiberglass cover plate over the hole, and install the fitting through the cover plate.

Be sure to protect the hose from abrasion and excessive heat (140°F). LPG hose should run through the top of lockers rather than through their bottoms. Support the hose every 18 inches with nylon cable clamps.

Gas Detectors

Gas detectors add an additional level of saf| ety to an LPG installation. “Sniffers” constantly monitor the air for the presence of LP gas, activating an alarm when they detect gas at about 10% of minimum explosive level.

Install the gas sensor where gas is likely to accumulate, i.e. as low as possible and near the range.

Recommended Cylinders

Aluminum

Lighter than steel

Doesn’t rust – ideal for marine applications

For specs and dimensions:

Manchester DOT Catalog

*Sizes and shapes may vary according to brand

Fiberglass/Composite

Lighter than steel

Doesn’t rust – ideal for marine applications

Translucent body allows you to see the propane level

Must be re-certified every 5 years, 15 year lifespan

For specs and dimensions:

Ragasco fiberglass cylinders

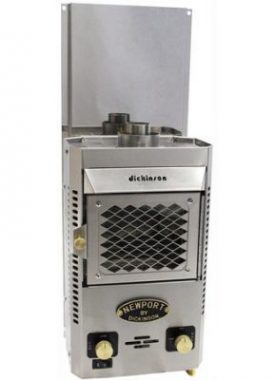

Boat Barbecues

Stainless Steel

Some models come with Rail Mount and Low-Pressure Kits